ISO 22343 Comprehensive Guide

ISO 22343-1 is the new standard for testing Vehicle Security Barriers (VSBs), superseding and replacing the old IWA 14-1 and PAS 68 standards, which are now both withdrawn.

Since late 2023, the industry has been adjusting as test centres work to receive their ISO 22343-1 accreditation. From 1st March 2024, the UK’s NPSA will only recognise VSBs tested under ISO 22343-1. VSBs tested before this will still be considered for entry into the NSPA’s Catalogue of Security Equipment.

ISO 22343-2, which covers how VSBs are used, has also been released and replaces IWA 14-2 and PAS 69, which are now also withdrawn.

Contents

- Why ISO 22343 Matters

- The Background and Development of ISO 22343

- How ISO 22343 Is Structured

- How ISO 22343 Improves on Past Standards

- How Vehicle Security Barriers Are Tested and Rated

- Understanding an ISO 22343 Performance Rating

- The Performance Rating

- How to Choose and Use Vehicle Security Barriers

- Identifying Threats with a Vehicle Dynamic Assessment

- Operational Requirements

- Assessing and Designing Sites

- Types of VSBs

- Installation Guidance

- Looking to the Future

Why ISO 22343 Matters

ISO 22343 is an international standard that sets out how to design, test, rate and use vehicle security barriers (VSBs). These VSBs which include street furniture products such as bollards, planters, litter bins, seating, cycle stands and road blockers, are installed to protect people, buildings, and public areas from threats involving vehicles, especially from hostile vehicle attacks like ramming incidents.

By following ISO 22343, manufacturers, security planners, governments and other relevant parties can make sure they are using barriers that meet clear, globally accepted safety standards.

Before ISO 22343 was created, different countries had their own testing standards. For example, the UK used PAS 68, and there were other regional standards like the IWA 14 standard. These different approaches often made it hard to compare vehicle security barriers or set international guidelines.

ISO 22343 was developed and officially introduced in September 2023 to solve that problem. It brings everything together into a single, unified framework that everyone can use, no matter where they are in the world.

The Background and Development of ISO 22343

The idea for ISO 22343 came out of a real and growing threat. Over the past few decades, vehicles have been used in deliberate and malicious attacks on crowds and sites. In response, governments and private organisations began looking for better ways to prevent these attacks, especially in busy public spaces like city centres, stadiums and event venues.

The International Organisation for Standardisation (ISO) created ISO 22343 to solve this issue. It was developed by ISO Technical Committee 292, which focuses on security and resilience. The committee worked with experts from around the world to make sure the new standard could work in different regions and environments.

As one of the oldest non-governmental organisations, the ISO have been bringing global experts to agree on various things from making a product to AI to quality management since 1946, enabling trade and cooperation between people and companies all over the world.

In the UK, ISO standards are published by the British Standards Institution (BSI), the official national standards body.

How ISO 22343 Is Structured

ISO 22343 is made up of two parts. Each part deals with a different aspect of vehicle security barriers.

The first part, ISO 22343-1, focuses on performance requirements. It explains how to test a barrier using a vehicle impact, how to measure the results, and how to rate the barrier based on how well it performs.

The second part, ISO 22343-2, is about practical application. It gives guidance to people who use or install the barriers, helping them choose the right type of barrier, install it correctly, and make sure it fits with the overall safety plan of the site.

How ISO 22343 Improves on Past Standards

ISO 22343 combines the safest features of previous standards while introducing new improvements.

Vehicle categories and weight ranges have been updated to reflect modern traffic and commercial vehicles, and it also includes new rules about how testing facilities must be set up so that tests are more consistent.

The stricter pass/fail criteria introduced in ISO 22343 means that vehicle security barriers must perform to a higher standard. The change to debris limits helps reduce the risk of secondary hazards for people who might be nearby. And the detailed video recordings of each test give a clear, objective record of how the barrier performs.

How Vehicle Security Barriers Are Tested and Rated

ISO 22343-1 provides detailed instructions for testing vehicle security barriers. The goal is to simulate a real-world crash where a vehicle tries to drive through a protected area. The VSB is then judged based on how well it stops the vehicle and how much damage occurs.

In the test, a vehicle is driven at a set speed into the VSB. The type of test vehicle, its weight, and speed are all carefully selected to match realistic threats. For example, one test might involve a light car going 50 kilometres per hour, while another might use a heavy truck moving at 80 kilometres per hour. These scenarios are designed to test the VSB’s strength under different conditions.

It is a common misconception that a VSB is simply passes or fails ISO 22343 testing. In reality, the impact testing covers a wide range of variables, such as different vehicle types and weights, speed of the vehicle and angle of impact, although a test crash can still fail if it does not meet the specified performance requirements. Therefore, it is important that the correct rating is selected for the application and/or scenario.

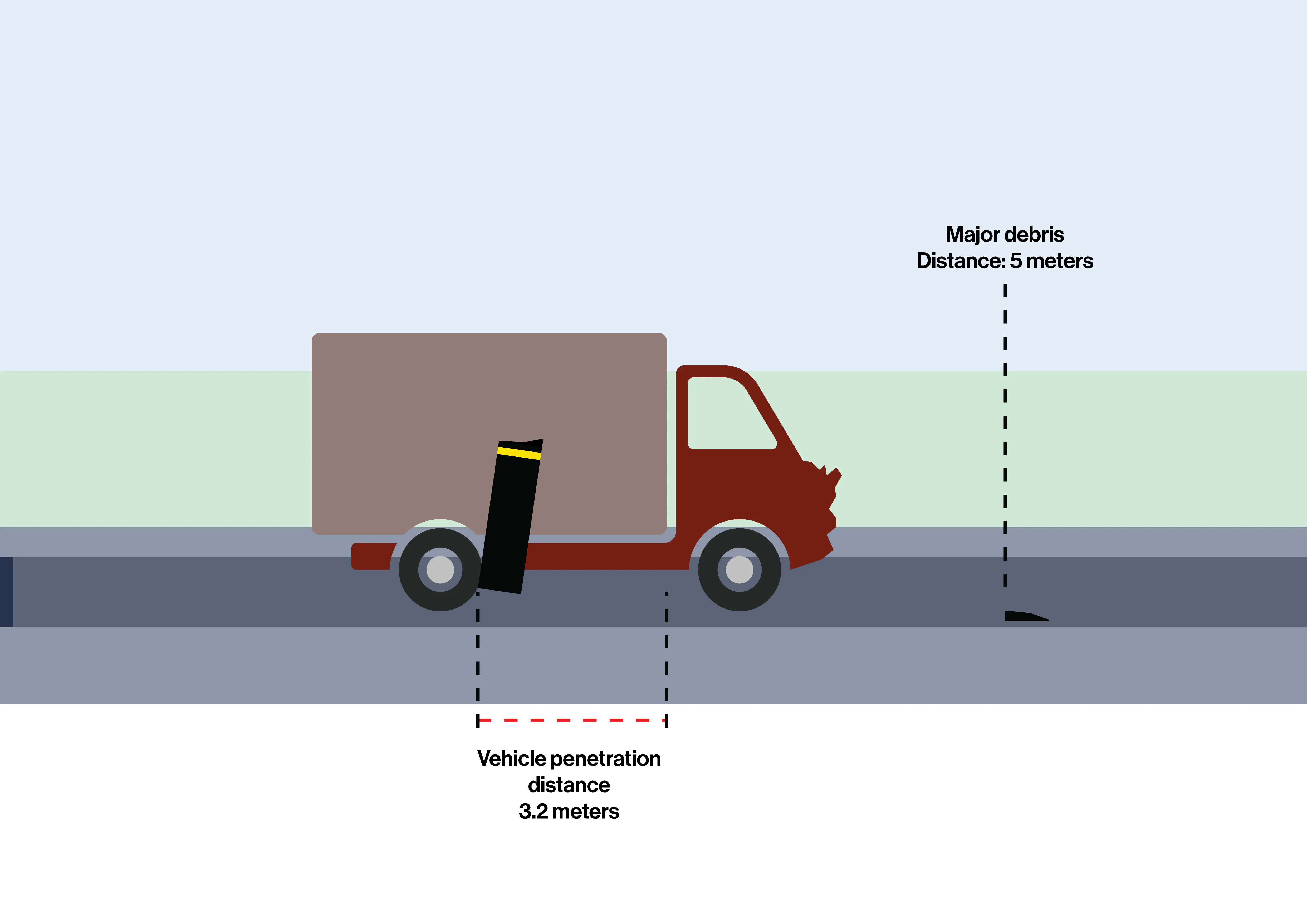

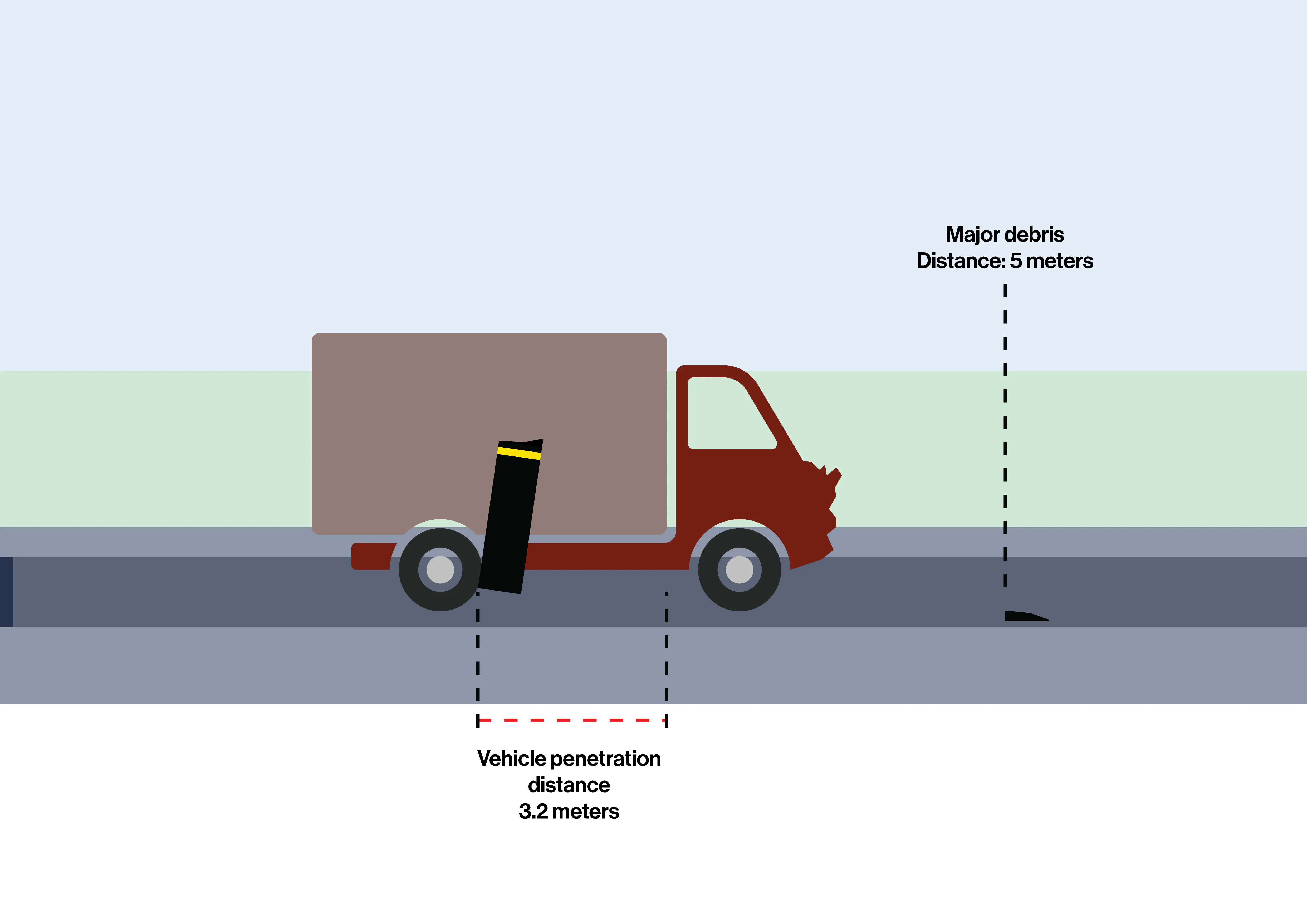

After the test crash, several measurements are taken. One key measure is how far the vehicle gets past the vehicle security barrier, known as vehicle penetration distance which is measured in metres from specific datum points on the vehicle and the product. If the vehicle breaks through and travels beyond 25m, the VSB fails the test. A full breakdown of the specific performance requirements, including vehicular penetration, are covered below.

One important update in ISO 22343-1 is the requirement to use high-quality video cameras during testing. The test house must now provide a real-time panning camera that sits perpendicular to the vehicle approach path, that records to full impact sequence. In previous standards, this was only a recommendation.

Understanding an ISO 22343 Performance Rating

To fully understand how ISO 22343 evaluates and rates vehicle security barriers, it's useful to look at an example test performance rating. It uses a structured format that looks like this:

V/3500[N1]/80/90:3.2/5.0

Test Method

V/3500[N1]/80/90:3.2/5.0

The first letter, in this case “V” shows the test method that has been carried out, in this case “Vehicle”. It is a standard prefix used across different performance rating systems within ISO 22343.

Vehicle Mass & Classification

V/3500[N1]/80/90:3.2/5.0

The next part, (3500[N1] in this case), refers to the type and weight class of the vehicle used in the test. The number refers to the vehicle’s weight in kilograms (3,500 kg) and the classification “N1” points to the vehicle’s classification.

Impact Speed

V/3500[N1]/80/90:3.2/5.0

The third element, “80”, represents the vehicle's approach speed at the moment of impact, measured in kilometres per hour. In our example, the truck was traveling at 80 km/h. This is a relatively high-speed test scenario, indicating a serious vehicle threat such as a ramming attack.

ISO 22343 allows for the testing of the following impact speeds (km/hr):

- 16

- 32

- 48

- 64

- 80

- 96

- 112

Impact Angle

V/3500[N1]/80/90:3.2/5.0

Following the speed, “90” indicates the impact angle in degrees. A value of “90” means the vehicle struck the vehicle security barrier head-on, perpendicular to the datum line. This is the most direct and demanding type of impact. ISO 22343 allows for a range of impact angles, depending on the anticipated attack method or real-world layout of the location. A 90-degree test is generally considered the most common and severe.

Penetration Distance

V/3500[N1]/80/90:3.2/5.0

This part of the classification, “:3.2”, shows the penetration distance of the vehicle after impact, expressed in meters. In this case, the vehicle travelled 3.2 meters past the front edge of the barrier before coming to a stop. This measure of effectiveness means the shorter the penetration distance, the better the barrier performs. If the vehicle had travelled more than the allowed maximum distance, or remained drivable after the impact, the test would have been considered a failure.

Debris Dispersion

V/3500[N1]/80/90:3.2/5.0

The final part of the performance rating, 5.0 in this case, is a measure of the maximum recorded distance of major debris 2kg or more past the VSB datum line, in metres.

Major debris is now classified as any piece of VSB, vehicle or ballast totally detached during the impact whose mass is >2kg. The maximum major debris dispersion is still measured to the furthest edge of the outermost piece.

This is significantly tightened compared the older PAS 68 and IWA 14 standards, which allowed much heavier fragments of up to 25 kilograms.

Although debris dispersion does not form part of the pass/fail criteria, it remains a crucial metric that helps security engineers visualise test outcomes more effectively. Simply stopping the vehicle isn’t enough if the impact creates dangerous secondary hazards. Debris dispersion affects safety and design decisions, ensuring that the VSB absorbs impact cleanly, minimises fragmentation, and ultimately provides manufacturers with a competitive edge.

The Performance Rating

Together, the full code example code we’ve provided, V/3500[N1]/80/90:3.2/5.0 tells us that a 3.5-ton light goods vehicle was crashed head-on at 80 km/h into the barrier, the VSB allowed 3.2 meters of penetration, and the debris from the impact was dispersed up to 5.0 metres.

A performance rating like this allows security planners and buyers to quickly compare and choose vehicle security barriers based on the specific threat levels they are trying to guard against. For example, a site at risk from light passenger cars might only need protection rated for 1500 kg at 50 km/h, whereas a critical national infrastructure site could require testing against 7500 kg at 80 or even 100 km/h. ISO 22343 makes these comparisons clear and reliable.

How to Choose and Use Vehicle Security Barriers

ISO 22343-2 focuses on the real-world use of vehicle security barriers. It explains how to figure out if a VSB is needed, and what type would be best. There is no “one size fits all” design and each site will require an informed and specific solution.

Once the threats are identified, planners must write an Operational Requirement (OR). This is a clear document that outlines what the VSB must do. For example, the OR might say the VSB needs to stop a 7.5-ton truck traveling at 60 kilometres per hour with less than one metre of penetration. The OR helps guide all decisions about which VSB to choose and where to place it.

The second part of ISO 22343 also talks about how to fit barriers into their surroundings. In urban areas, it’s important that barriers don’t block pedestrians, emergency vehicles, or deliveries. They also shouldn’t make the area look or feel unsafe unless needed.

Identifying Threats with a Vehicle Dynamic Assessment

It all starts with a risk assessment, where the threats that a site might face are looked at. For example, a busy pedestrian area near a government building may face a higher risk of vehicular attack than a rural warehouse.

Although a risk assessment and a Vehicle Dynamics Assessment (VDA) sound similar, they have distinct roles within the security planning process.

A risk assessment is a broader strategic evaluation that analyses threats, vulnerabilities, and the potential consequences of hostile vehicle attacks. This process considers who or what might be targeted (e.g., people, buildings, public spaces), what kinds of attacks are likely (e.g., vehicle-borne IEDs, ramming), and the level of protection required to mitigate those risks. The outcome is a set of Operational Requirements (ORs) that define what the security system must achieve.

A Vehicle Dynamics Assessment (VDA) is a technical and site-specific assessment that supports the implementation of the Operational Requirements. It looks at how a vehicle might realistically approach the site or target area. This includes the vehicle’s potential speed, angle of approach, acceleration distance, access routes, turning radii, road gradients, and site layout. The VDA helps determine the performance rating needed for vehicle security barriers and guides decisions about where and how barriers should be installed.

Operational Requirements

Operational requirements (ORs) are the practical outcomes that the security solution must achieve and forms the backbone of all decision-making when selecting or designing a VSB system.

An operational requirement is not simply ‘stop a vehicle’, it must go deeper, addressing the site’s purpose, potential threats, surrounding activity, and performance expectations.

This involves understanding:

- The function of the site: Is it a public shopping centre, a military base, or a transport hub? Each requires different VSB solutions based on activity, pedestrian use, and access patterns.

- The level and type of threat: Is the likely threat a hostile vehicle carrying explosives, a high-speed ramming attack, or accidental intrusion by an unauthorised vehicle? Knowing this helps determine the required vehicle mass, speed, and direction for consideration.

- Critical zones: What areas must be protected, such as entrances, pedestrian walkways, queuing zones, building façades, or utility access points?

- Traffic flow and accessibility: What must remain accessible for legitimate users like deliveries, emergency services, or staff?

Assessing and Designing Sites

After establishing the operational requirements, it is time to turn to on-site assessment and design, which involves mapping the physical environment and identifying how to integrate barriers without disruption.

Site assessment and design differs greatly from one location to another, however some key aspects in planning include:

- Vehicle approach routes: Planners must consider all potential directions from which a vehicle could approach a target area.

- Site layout: VSB performance is strongly influenced by the impact angle and approach distance. A VSB that works at a 90° impact angle may not be effective at 45°, and stopping distances can change dramatically with terrain grade or road conditions.

- Ground conditions and utilities: Underground utilities like gas, electricity and sewage may restrict the type or depth of barrier that can be installed. For example, some anti-terror planters require deep foundations that cannot be installed on shallow subgrades.

- Pedestrian safety and accessibility: VSBs must not create hazards for pedestrians or prevent access for people with disabilities. Safe stand-off zones and adequate walking spaces must be taken into consideration.

- Environmental factors: Especially in civic or heritage locations, barriers must blend with the environment. ISO 22343 recommends integrating VSBs into furniture, landscaping, or architecture where appropriate, for example by using compliant planters, benches and litter bins where appropriate.

Types of VSBs

ISO 22343 primarily categorises VSBs as passive or active, and this distinction is foundational in selecting the right VSB type to meet both the operational requirements and the functional dynamics of a given site.

Passive Barriers

Passive barriers are static, immobile structures designed to permanently prevent unauthorised vehicle access. Once installed, they remain in place at all times and do not require any human or electronic interaction to operate. Their simplicity and reliability make them suitable for protecting areas where vehicular access is never permitted, such as pedestrian-only zones, monuments, or vulnerable infrastructure.

Common examples of passive barriers include fixed bollards and large-scale street furniture such as bollards, planters, litter bins, seating, cycle stands and road blockers.

One of the key advantages of passive barriers is their minimal maintenance and failure risk. Because there are no mechanical or electrical parts, passive VSBs are immune to power loss, system malfunctions, or cyber threats. However, this same static nature means they must be carefully planned within the site design, particularly in high-traffic or mixed-use spaces. Their placement must allow for emergency access, pedestrian movement, visibility, and integration with other site functions.

From a design perspective, ISO 22343 encourages the aesthetic addition of passive barriers into the built environment. For example, crash-rated planters or benches can be strategically placed to preserve the architectural feel while simultaneously preventing hostile vehicle intrusion. This is particularly relevant in city centres or heritage areas, where traditional fencing or bollards might take away from visual appeal.

Active Barriers

Active vehicle security barriers are mechanical or electromechanical systems designed to move, retract, rise, or swing to allow controlled vehicle access. They are typically integrated into access control systems, responding to authentication processes such as RFID badges, keypads, license plate recognition, or operator commands.

Active VSBs are essential at locations where authorised vehicle entry is required, such as government facilities, secure corporate sites, military bases, and data centres.

Active vehicle security barriers include devices such as rising bollards, wedge barriers (also called road blockers), sliding crash gates, retractable barricades, and swing-arm crash gates. These barriers must be designed not only for high impact resistance but also for reliability, response time, and safe operation under normal conditions.

Due to their mechanical nature, active barriers come with additional planning and infrastructure requirements. Power supply, control units, emergency override functions, and integration with surveillance and alarm systems must all be considered. Active systems are subject to routine maintenance schedules, including checks on hydraulic systems, motors, pressure sensors, limit switches, and control electronics.

One challenge with active systems is their dependence on consistent operational conditions. Failures in power, software, or human error can result in compromised security.

In many scenarios, a hybrid approach is ideal. For example, a facility might use fixed passive barriers around its perimeter and reserve active barriers at designated entry points. This provides a secure boundary while still allowing flexibility for day-to-day operations and controlled access.

Installation Guidance

No matter how well a vehicle security barrier performs during impact testing, its effectiveness in a real-world application depends entirely on whether it is installed correctly. ISO 22343 makes it clear that any deviation from the tested installation method, whether in foundation depth, anchoring configuration, barrier alignment, or spacing, may significantly compromise the performance of the VSB.

As vehicle security barriers are designed to transfer the energy of a high-speed vehicle impact into the ground, the structure beneath the surface must be engineered to absorb and dissipate those forces. This typically involves reinforced concrete foundations of sufficient depth, though shallow-mounted systems may be used where ground conditions do not allow for deep excavation. Shallower systems are only acceptable when they have been specifically tested and certified for the intended conditions, and planners must be cautious not to substitute a full-depth system with a shallow one without technical justification.

It is important to strictly adhere to the manufacturer's specifications during installation. Each certified VSB comes with a detailed installation manual that outlines the required procedures, materials, measurements, and tolerances. These are not optional guidelines; they are integral to the system’s performance. A barrier installed even a few degrees off-angle, or with inconsistent concrete curing, may perform very differently under real impact.

In most cases, the provision that a product has been installed exactly as tested and meets all relevant test report elements is sufficient evidence that the VSB meets its performance rating.

In cases where evidence needs to be verified, the installation should be overseen by experienced and quailed professionals who can complete quality control measures such as site inspections, photographs, and contractor certification.

Another critical factor is the alignment and spacing of the barriers. For example, bollards that are spaced too far apart may allow small cars or motorcycles to pass through, even if each individual unit is crash-rated. Minimum spacing distances based on different vehicle sizes and approaches must be evaluated during the design stage and verified at installation.

Maintenance and ongoing inspection are integral to long-term performance of vehicle security barriers. A scheduled maintenance regime be established from the start, ensuring that all VSB components are routinely checked for signs of wear, corrosion and accidental damage. This is especially important in weather variable locations, where constant exposure to rain, snow and ice can compromise foundations. Maintenance logs should be kept and periodically reviewed as part of the site’s overall risk management strategy.

Looking to the Future

It is expected that ISO 22343 will become even more important as spaces become more open and grow in popularity. Balancing between protection and freedom is exactly what ISO 22343 is designed to support.

Please Note: This guide is an interpretation and practical aid. For the complete requirements, please purchase and refer to the official ISO 22343 standard.